Custom Architectural Millwork services

If You can Dream it, we can make it

Architectural Millwork is nothing if not custom. Our services are simply that: customized. It is close to impossible to even list all of the possible things we can make, but if you need it and it’s wood related, we can probably do it. And we can do it in just about any species of wood, because for hundreds of years that’s what the McIlvains have done: source and inventory domestic & exotic hardwoods from all around the world.

When we added a planing mill, we expanded to linear mouldings and trim. Now with a full custom architectural millwork house, we can do pretty much anything that you can think of. Below, you will find some examples of our capabilities, but we urge you to reach out and let us know specifically what you are looking for.

In fact, give us a call at (800) 638-9100, and we can give you a tour of our facilities and talk in greater detail about how we can make your designs come to life.

Custom kitchen cabinets, libraries, even stand alone furniture. Our custom cabinet shop can draft, design, and execute your dream cabinetry in a variety of wood species.

Interior and exterior custom doors, gates, modern and traditional, composite and solid wood. Exotic and domestic species available and fully custom sizing and appearance.

Custom mouldings, stairs, linear and radius moulding, wainscoting, paneling, chair rail moulding profiles. From industry standard profiles to crazy, out of the box designs, we have made them all.

T&G ceilings or feature walls custom moulded and finished, ready for installation. Design your look with hundreds of wood species, profiles and finish options to suit your vision

Interior and exterior priming services for siding, trim mouldings. Offered in 3 different options to suit any wood species or top coating.

Pergolas, gates, trellis, decks, railings, gazebos, rafter tails, balconies, entryways…

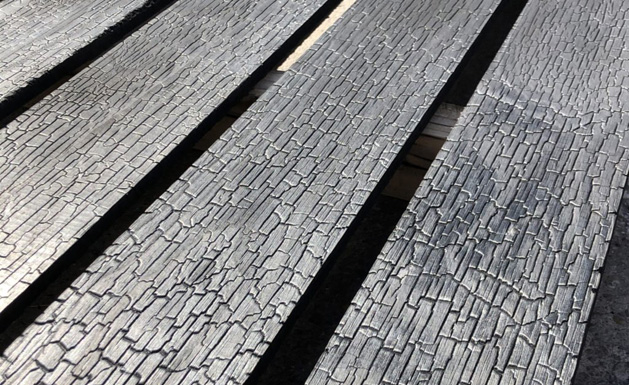

Shou Sugi Bahn (torched) siding, wire brushed or hand scraped siding/flooring

Solid wood or veneered beams in all shapes and sizes and even in massive lengths

Interior & Exterior, traditional stains, clear coats, nautical, and epoxy finishes

Wide plank flooring, solid wood, engineered, custom laid up flooring

Skip planing, S4S, S2S, or even milling to precise dimensions to meet your manufacturing parts lists. Need crown, base, chair or any other kind of trim moulding profile? We can run it, and custom mouldings are our bread and butter with over 3000 knife profiles and the ability to custom grind to meet your needs. Check out our Moulding Profile Library or give us a call about a custom profile for your project.

We can groove your tropical decking for hidden fasteners or your rainscreen siding as well as provide sanding and finishing or even make decking tiles. We also supply clips, screws, end sealer, oil, anything you need for your deck and/or siding installation. Make sure to check out our Alpha line of finished Cladding/Siding